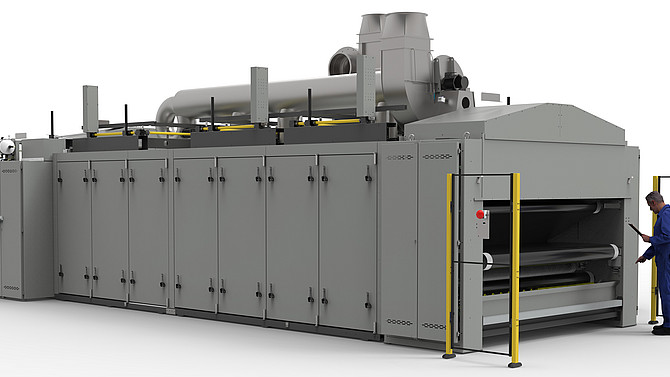

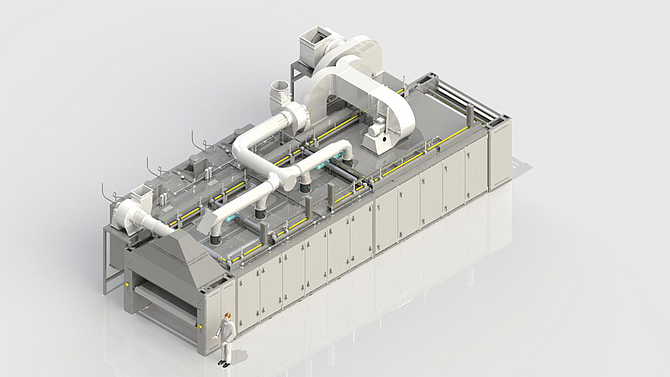

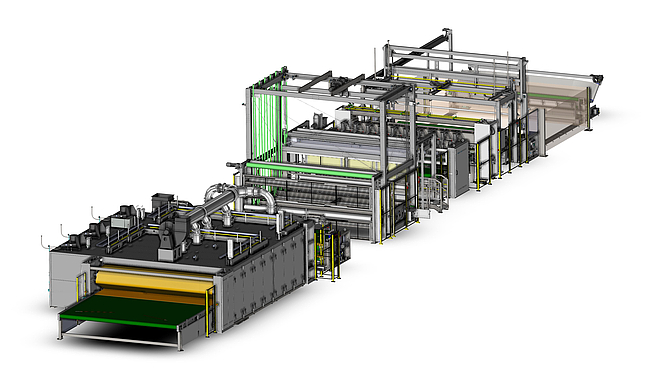

TopConMAP Double Belt Oven with either Air-Through or Air-Impingement Ventilation Mode

Compact allrounder

The newly developed TopConMAP (MultiAirPrinciple) double belt oven is a compact all-rounder in a modular design. This oven combines all the well-known and well-proven features of our TopConLP and TopConHP double belt systems in one system. This means, the oven offers adaptable air-through handling per metre and highly efficient impingement ventilation from both sides. The highlights of this oven are its high flexibility, compact design and the newly developed air ventilation principle, which ensures that there is negative pressure on the entire outer oven insulation for optimal leak tightness.

Technical Data

Useful working width: | 1.200 - 6.000 mm |

Zone length: | 2.000 mm |

Free clearance between the conveyor belts: | max. 300 mm |

Heating media: | Natural gas, LPG, heat transfer oil, steam, electric energy |

Working temperature: | max. 240 °C |

Fibres: | PES, cotton, recycled fibre, flax, hemp, Kenaf,wood fibre and sheep wool, PP, PE, BiCo |

Weight range: | 20 – 10.000 g/m² |

Web density: | max. 250 kg/m³ (in conjunction with calibrating rollers) |

Production speed: | max. 200 m/min |

![[Translate to English:] Schott & Meissner Maschinen- und Anlagenbau GmbH [Translate to English:] Schott & Meissner Maschinen- und Anlagenbau GmbH](/fileadmin/kbtheme/images/logo.svg)