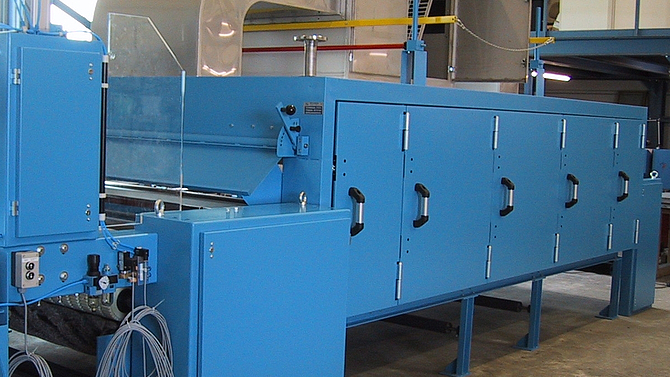

VapConHT Steam Oven

Used in nonwovens bonding by means of phenolic powder or epoxy resin

The steam oven manufactured by SCHOTT & MEISSNER is used in nonwovens bonding by means of phenolic powder or epoxy resin for either semi-curing or assisting in full-curing. The steam penetrates the fibre package and the thermal energy of the steam is used to activate the phenolic resin; this results in a first cohesion between powder and fibre. A double belt oven (TopConLP; AirConTS) is downstream to the steam oven in the full-curing process. Due to the pre-activation of the powder in the steam oven, the fabric web can be hardened in the double belt oven. A relevant thickness calibration can be undertaken via the double conveyor belt.

Technical Data

Useful working width: | 2.000 - 3.200 mm |

Zone length: | 2.000 mm, 3.000 mm |

Free clearance: | max. 250 mm |

Heating media: | Dampf, Wärmeträgeröl |

Working temperature: | max. 160 °C |

Fibre / application: | Baumwolle, Recylingfaser, Glasfaser |

Powder: | Phenolpulver, Epoxy |

Weight range: | 600 - 4.000 g/m² |

Production speed: | max. 15 m/min |

![[Translate to English:] Schott & Meissner Maschinen- und Anlagenbau GmbH [Translate to English:] Schott & Meissner Maschinen- und Anlagenbau GmbH](/fileadmin/kbtheme/images/logo.svg)